Inspection for Quality Assurance (QA) and Quality Control (QC)

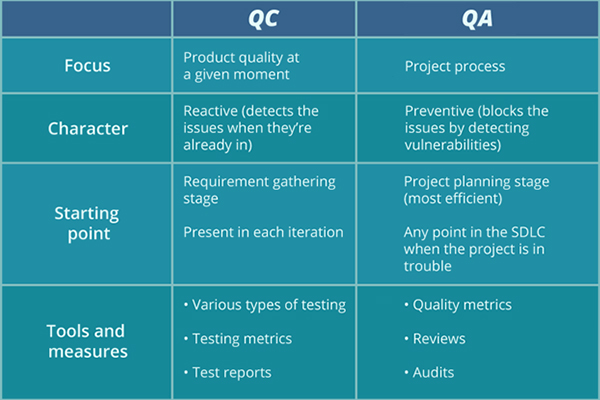

Quality Assurance (QA) and Quality Control (QC) are often confused as being the same process. However, the two processes are distinct.

Quality Assurance

The purpose of QA is to inspect the process that manufactures products. In other words, QA is a process that looks to improve the product development in order to eliminate defects in manufactured products. Inspection relating to QA does not typically involve NDT nor mechanical testing but rather, uses qualitative methods to identify gaps and anomalies in the process.

Quality Control

QC is carried out after QA and involves inspection of the product. The QC process involves activities such as NDT to ensure the quality of the product will operate as intended and for a specified number of cycles (if applicable) before failure. Mechanical testing may also be performed on one part per batch or per “X” number of batches. The number of batches is up to the company and individuals involved in the manufacturing process. The purpose of QC is to detect flaws and to determine if the defect is acceptable or rejectable for service.